Description

Overview:

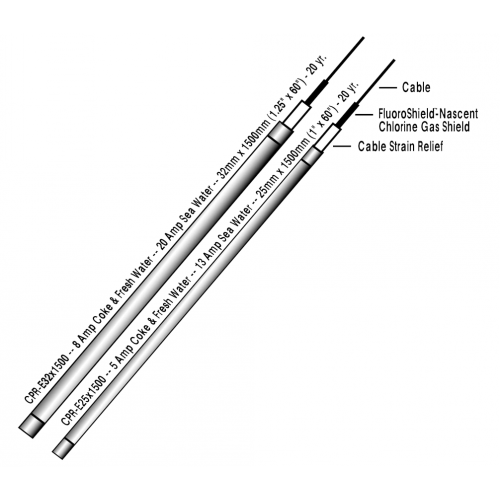

The Econo-Tubular-Anode is a high quality but economical tubular anode ideal for applications where a SINGLE – one anode per cable – is preferred. 32mm x 1200mm. It is designed for the demands of deep anode beds, shallow beds and the earths natural waters. The specially designed end connection allows for quick custom cable lengths. Light weight construction provides ease of handling and economy of shipping.

This anode is manufactured using the same special arc-plasma spray processing developed by CerAnode in the mid 80s. The connection is of the highest quality electrically and environmentally having a copper-to-titanium resistance of less than 100 micro ohms with an environmental MultiSeal encapsulation fully resistant to nascent chlorine gas. It also features a FluoroShield cable guard. The anodes catalytic EMMO coating is tightly sintered to its titanium substrate resulting in a truly unique surface architecture providing an abrasion resistant surface protecting it from injury during installation. It is one-of-a-kind among the many MMO technologies available in the marketplace today. It features iridium as its primary catalyst which the Chemistry and Physics Handbook classifies as the most inert material known to man. The proprietary nature of the catalyst mixture and deposition process results in a very special ceramic anode product.

Specifications:

- Anode Catalyst – CC-TIR-EMMO (Iridium – Tantalum – Titanium).

- Deposition Method – Arc-Plasma Spray Processing.

- Surface Architecture – Hardened Ceramic Exhibiting Abrasion Resistance.

- Substrate Material – ASTM B-338 Commercially Pure Titanium.

- Connection Resistance – 100 micro ohms.

- Tube Wall Thickness – 0.9 mm.

- Apparent Dissolution Rate – 1-10 mg/A-Yr – electrolyte dependent.

- Anode Weight – 0.6kg plus cable.

- Weighted version (optional) Approx. 3.5kg.