Dresser couplings are the original and best compression type pipe joining device. Allowing slight misalignment, vibration, expansion and contraction with a very simple and rapid installation process. If you can do up a nut and bolt you are capable of installing a Dresser coupling.

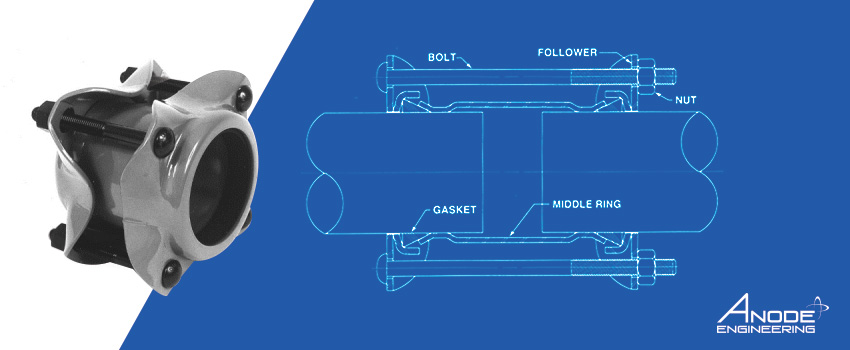

The basic Dresser Coupling is made up of a central ring and one follower ring at each end, in between the central ring and these follower rings sits a gasket. The central ring is flared so the tapered gasket sits within the flare. Long carbon steel bolts run the length of the coupling connecting to both following rings. The flat backend of the gasket is compressed together by sequentially tightening the bolts that pull the two follower rings closer together creating a pressure seal of up to 1500 PSI.

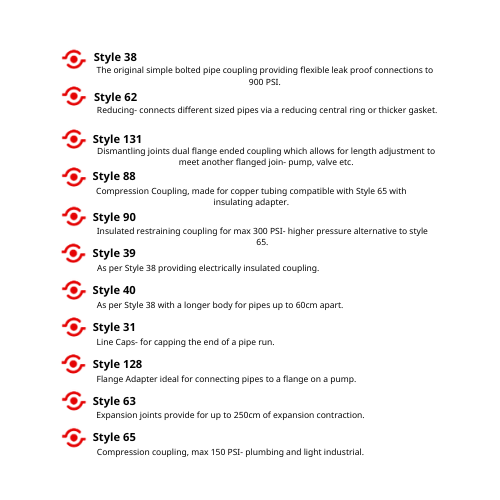

There is a huge range of Dresser couplings available from Anode Engineering, mainly divided by seal only models or seal and restrain coupling models which seal and stop pipe pullout. The couplings can also be electrically insulated or non-insulated allowing D.C. current to flow for Cathodic Protection (CP) systems.

The gaskets used in Dresser couplings are specific to the product being transported within the pipeline. They come armored or non-armored with the difference being that the armored gasket features a metallic spring which conducts electricity to allow CP current to flow between the pipes. The non-armored gaskets will allow pipes of dissimilar metals to be joined or prevent CP current flow. Following is a list of gasket materials and their common uses:

The gaskets used in Dresser couplings are specific to the product being transported within the pipeline. They come armored or non-armored with the difference being that the armored gasket features a metallic spring which conducts electricity to allow CP current to flow between the pipes. The non-armored gaskets will allow pipes of dissimilar metals to be joined or prevent CP current flow. Following is a list of gasket materials and their common uses:

- Buna N Grade 42- Nitrile- Max 100˚Celsius. Mainly used for oil, hydrocarbons, condensates and gasolines.

- Buna S Grade 27- Max 100˚Celsius. The most widely used gasket material for fresh and salt water, natural gas, air, alkaline solutions and some refrigerants.

- Viton/ Fluorocarbon Max 176˚Celsius. Good for alcohols, organic acids, nitrogen compounds, vegetable oils and greases.

- Butyl- Max 250˚Celsius resistant to hot air, steam, hot water, aqueous solutions.

- EPDM- Max 150˚Celsius- resistant to Ozone, Oxygen, hot water, glycols, hydraulic fluids, ketones and alkalines.

- High temp- Max 650˚Celsius- asbestos replacement for high temp and abrasive atmospheres.