Description

Overview:

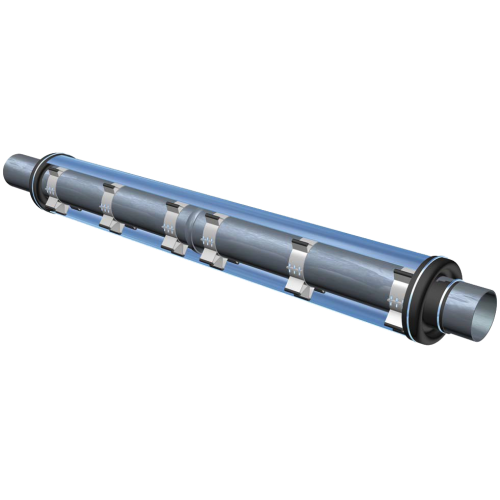

An extremely tough and durable heat fused fluid bed thermo set cross-linked polymer coating is offered on steel casing spacers/isolators 4 inches and larger, with 8 inches and 12 inches band widths. The cold formed steel casing spacer/isolator band (risers where applicable) and studs for runner mounting are grit blasted, heated and fusion coated with a cross-linked epoxy polymer formulation, providing a minimum 0.010 (0.254mm) thick coating over the entire metallic surface. A post cured cycle strengthens the bond and provides an even more uniform coating. Other heat fused formulations are also available for custom orders and applications. The runners are attached with 3/8 inches diameter studs, which are fusion welded to the band before it is powder coated. They are recessed far below the wearing surface of the runner. After the runner is anchored to the band, the stud counter-bore is filled with specially formulated caulk to assure a water tight seal for the stud and the locking fastener.

Benefits / Features:

- Low Labour Costs – May Be Installed By One Person Glass Reinforced Nylon or Polyester Runners Offer Low Coefficient of Friction = 0.1 to 0.6.

- Glass reinforced nylon or polyester runners offer 18,000 PSI (1,265kg/cmsq).

- Compressive strength riser height may be specified for specific positioning of carrier pipe within casing heavy duty.

- PVC inner liner provides protection for pipe and/or coating offers excellent corrosion resistance.

- May be used for long pulls and/or heavy pipe installations.

- Designed to last for the life of the piping system.

- PVC liner provides back-up isolation.

- Deeply embossed flanges offer added strength during tightening of flange bolts.

- Eliminates the need for blown sand or pea gravel available with 8 inch or 12 inch bands. 10 or 7 gauge risers may be ordered.